A whole series of procedures and interfaces already make it possible to hand over a task to the robot by demonstration, such as:

- Marking of a working area via positioning to the corresponding corner points.

- Manual tracing of the desired path

- Demonstration of speed or force application

- Evaluation of necessary acceleration and dynamics by motion tracking of e.g. human sanding movements

However, it only becomes interesting for efficient, automatic use when robots are trained in certain skills that they can later retrieve independently, such as ‘recognize a component edge and turn around’.

LEROSH aims to discover these ‘robot skills‘ and develop simple learning procedures for them.

In the end, craftsmen should be able to train the robot for the respective need in exactly its appropriate application.

In which applications do craftsmen work ‘hand in hand’ with the robot, i.e. collaboratively?

Or perhaps better: Where can still unknown sanding tasks even be processed fully automatically with the robot?

At LEROSH, we want to investigate which interaction between man and machine is best suited to the craft.

User

Interface

The Robot Operating System (ROS) is a set of software libraries and open source tools that works like an SDK (Software Development Kit) and supports the development of robotic applications.

The use of these open-source tools has been spreading rapidly since its beginnings in 2007, as basic principles and tools already developed with ROS are made freely available to all users.

This also enables smaller companies to develop and commercialize their own applications.

Important building blocks are:

- Hardware-software communication

- Software libraries

- Data logging

- Visualization and simulation

Technically challenging for the software development is to determine the correct combination of all involved system components:

LEROSH relies here on the already revised, better standardized ROS 2.

How and where are all involved components and programs linked (plumbing) ?

Where can software modules simplify the systems for the user or make them connectable?

How to deal with different robot systems ?

Which modules could later also function as a functioning robot app or a robotics toolbox for the craft?

The intended integration and implementation of the solutions in an intuitively operable framework for cobots – as well as for conventional robot systems – enables the development of a holistic approach in LEROSH, which, compared to the state of the art, is not only suitable for selected special cases, but enables increased manual performance in a broad field of applications. This makes it possible to realize greatly improved and more flexible automated processing of different individual parts even without programming effort.

The human-machine interface is a function or component of a particular device or software application that allows people to operate and interact with machines.

From emergency stop button to Hololens

In robotic application systems, there are on the one hand numerous necessary functions and components (e.g. robot control panel for safe machine operation), and on the other hand also a growing number of hardware and software components which, in their special configuration, can greatly simplify or accelerate the human handling of machines.

LEROSH will also be used to test the applicability of such systems for handcraft suitability, e.g.:

– Computer vision systems that can be trained to recognize specific elements and movements (>e.g., component recognition or gesture control).

– Infrared-based motion (movement) trackers that can quickly and accurately detect position and orientation in space

– AR (augmented reality) glasses for 3D process monitoring and control.

With which interaction between human, robot and component can the use be simplified, accelerated, made more flexible?

User Requirement

Bundle knowledge and experience from different disciplines and share solutions!

In the project network, the practical robotics applications unfold in this way into positive feedback loops.

We want to show here how it can also work for other craftsmen under the areas of system, user, component.

Do you have further questions?

Or do you want to be informed regularly?

Discovering things yourself, trying out technology, figuring out new methods and learning from experiments.

With the right tools, practical experiences of success in crafts are still guaranteed.

Not work like the robots, but with them. Or even better: let them work.

The extensive automation and thus avoidance of activities that are hazardous to health is one of the main goals of the project:

- Less exposure to (sometimes toxic) dusts.

- Less risk of accidents, which has been the case up to now with the use of manual equipment

- Physical relief through the reduction of monotonous and strenuous work processes

Safe use is also ensured by the use of cobots, ergonomic tool attachments, practicable safety devices such as laser barriers or enclosures, and an end-to-end safety concept.

From Digital Native to Old Master…

The use of robotic systems can be taught in both education and training, as long as the user interface fits the task.

Programming

Cost-intensive, industrial solutions with long development periods focus on series application and usually cannot offer the flexibility required in the trade. In most cases, technology-driven development lacks a concrete objective and also the implementation know-how for the actual need.

LEROSH brings together process expertise (craft) and robot expertise (research) in the application. By means of practical feedback and simple learning procedures, the craftsman’s user know-how can itself become the basis for the generation of own robot processes that go beyond pure positioning.

It is not only the craftsman who must continue to develop; the robotics must also be adapted to the needs of the craftsman.

Why complicate things when they can be simple?

How many software programs does the user currently need to make the robot follow simple paths?

Currently, a number of programs are needed, such as CAD, CAM software, simulation, post-processors, control programs and many more.

With LEROSH, the robot application system will become a practical tool.

We search for the learning effect!

The goal of the LEROSH approach is an intelligent and interacting system, which can process components automatically – taught by the craftsman. Critical here is the formalization of the expert’s knowledge of how components are to be processed, the simplification of operation so that no programming knowledge is required, and the automation of processing for batch size 1.

This is only possible by making robots capable of learning, i.e. by allowing robots to learn how to process certain components, forms and materials on the basis of demonstrations and the skills of the craftsmen. Contact forces and other sensor data should be increasingly interpreted for this purpose and evaluated with machine learning to improve execution in terms of quality and possible component complexity. In addition, this information from the measurements can be used for automatic recognition of machining classes (e.g. geometry, material or quality), thus enabling extrapolation of the learned skills to unknown components.

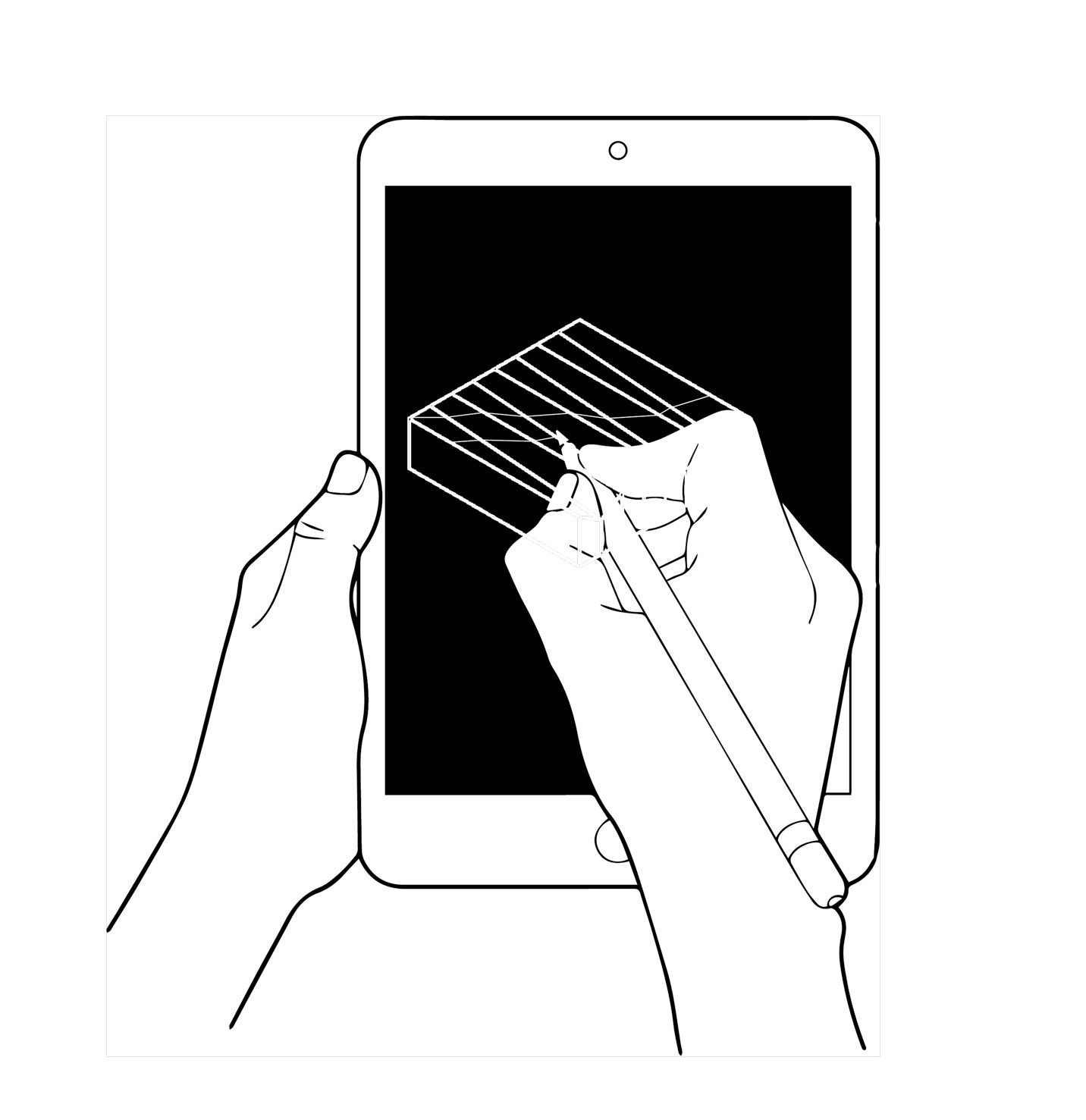

Innovative input devices like the one from Wandelbots enable manual robot positioning without programming.

LEROSH takes manual robot sanding one step further:

No programming and no positioning.

Based on learned robot skills, it should become possible in the sanding application to have the robot recognize or execute the work area and movement independently.

UX/UI Design

The whole workflow under control! Simulate 3D components and control the robot with just two fingers.

With the experts from Interactive Scape, applications become vivid and even self-explanatory.

Operate robots with complex simulation programs or simply control them with your smartphone? Perhaps this would even be indispensable for some manual tasks?

The art of UX design comes into play in the respective optimal user interface, maximally intuitive and playful in use.